- Home

- [Work] Project Story

- Continuously variable transmission development project I-HMT (Hydro-Mechanical Transmission)

Project Story Project Story

Continuously variable transmission development project

I-HMT

(Hydro-mechanical transmission)

Combines operability and transmission efficiency

Developing a groundbreaking transmission

Also called a "transmission," it is used in automobiles, tractors, etc.

It transmits the power generated by the engine to the wheels, and can change the engine's power output by increasing torque on slopes and increasing speed on flat roads.

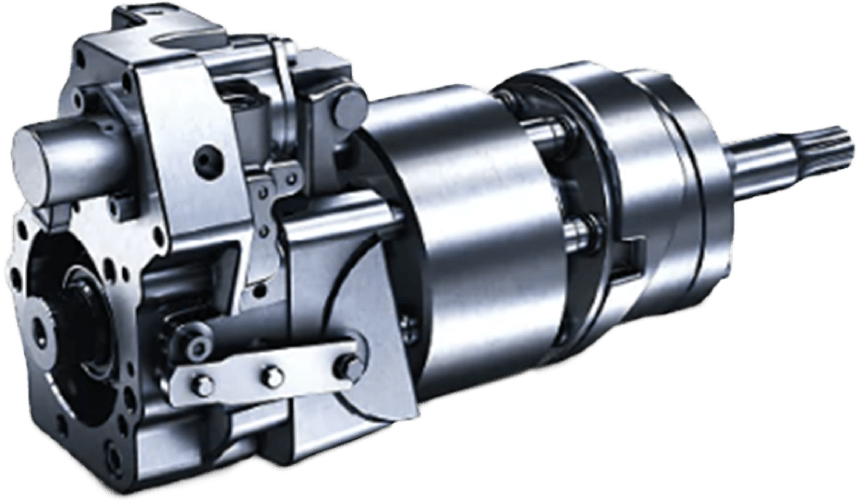

Normally, planetary gears are used to achieve a compact size and high torque, but here we will introduce the inside story behind the development of I-HMT, a small, continuously variable HMT (hydro mechanical transmission) that does not use planetary gears.

This is a revolutionary transmission that combines the operability of a hydraulic continuously variable transmission with the transmission efficiency of a stepped transmission.

Interview members

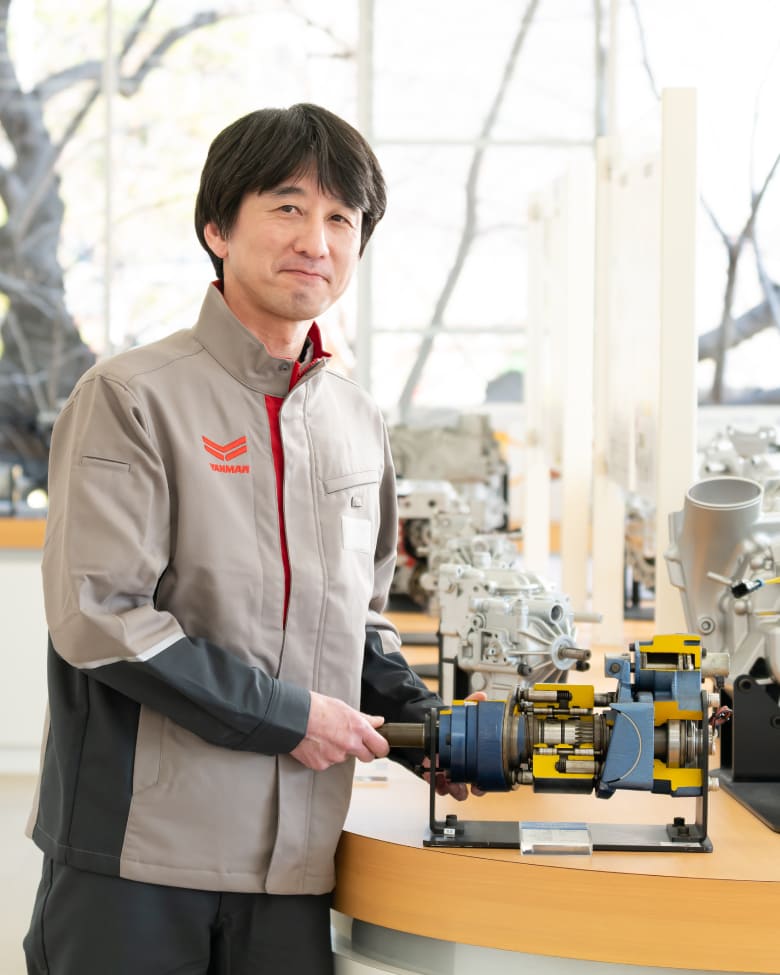

Development Department Product Development Department

Second product G

TT

Joined the company in 1998.

Since joining the company, he has been in the development department, where he is involved in hydraulic equipment design.

He is primarily responsible for the design of the I-HMT and HST introduced here.

We are currently proposing products and solutions such as HST and HMT that are suited to the specifications of domestic and overseas customers, including the Yanmar Group.

What are the features of the I-HMT that is installed in Yanmar tractors?

-

TTMr. Miss. -

I-HMT is the culmination of many years of technology and experience, and is a core technology suitable for the next generation of tractors.

Conventional HMTs (hydromechanical transmissions) generally use a complex planetary gear mechanism to split and integrate the flow of power, but I-HMT has succeeded in creating an HMT that does not use this planetary gear mechanism.

As a result, we were able to reduce the size by 30% compared to conventional HSTs of the same capacity, and at the same time succeeded in reducing losses by 10% (based on the results of our product research).

What are the advantages of not using planetary gears?

-

TTMr. Miss. -

Planetary gear mechanisms tend to be complex and have a large number of parts, but the I-HMT combines a simpler hydraulic control system and mechanical elements to achieve both efficient power transmission and compactness.

This has increased the design freedom of the tractor, contributing to the development of easier-to-use machinery.

This development project started at Yanmar, and when it was time to commercialize it, design and manufacturing were transferred to Kanzaki, who then proceeded with mass production. What role did you play in this process?

-

TTMr. Miss. -

The adoption of this new mechanism entailed many technical challenges.

Kanzaki, with its many years of experience and proven track record in the manufacture of hydraulic equipment, was the perfect fit to take on the challenge of commercializing the I-HMT.

In the transition to mass production, we faced various problems, such as parts breaking during confirmation testing and measures to improve mass production costs.

We took measures such as adopting a special surface treatment technology for the sliding parts to improve durability and reliability, and repeatedly prototyping and checking the dimensions and tolerances of each part to improve the life of the bearings and the responsiveness of the hydraulic control.

Its reliability has been thoroughly verified by conducting individual durability tests and tractor evaluation tests.

Although it was difficult to balance cost and quality improvement, the Materials Department, Production Department, and Quality Management Department came together and established a new assembly line and operating equipment specifically for I-HMT. By discussing the process, we were able to build a system for the stable supply of high-quality products.

In order to avoid producing non-conforming products, I worked closely with suppliers and worked hard on mass production design.

What assets have been gained through development?

-

TTMr. Miss. -

The development of the I-HMT was the fruit of teamwork, with engineers with diverse expertise coming together and using their respective strengths to solve problems.

Through this experience, I was able to gain in-depth knowledge about new surface treatment technologies, heat treatment technologies, and materials.

We have also been able to build strong relationships and networks of trust within the group and with our suppliers, which we believe will be a major driving force in our future design and development.

The I-HMT is still used as a key component in Yanmar tractors today, and will continue to evolve toward further improvements and new technological innovations in the future.

Another Story