Gear Processing Machine

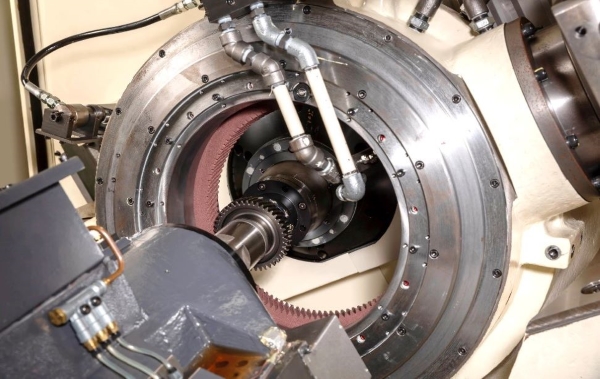

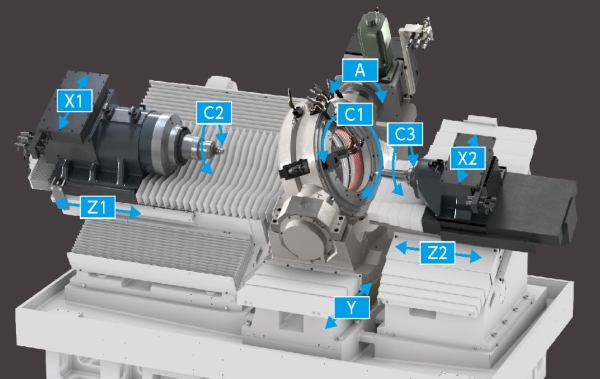

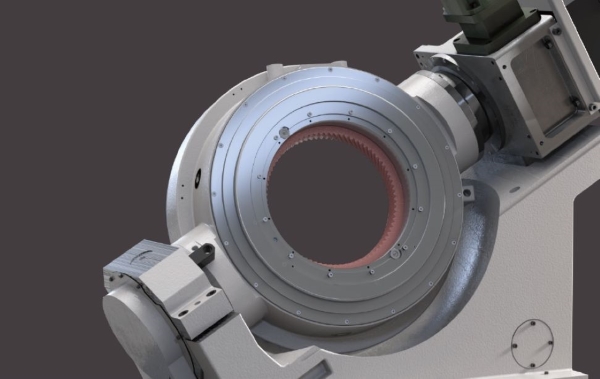

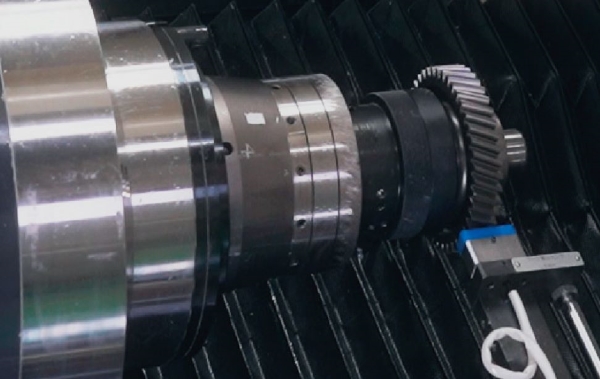

Gear Honing Machine

High speed rotation of the grinding wheel allows for machining with small cross angles

| Maximum workpiece outer diameter (mm) | 260 |

|---|---|

| Maximum workpiece face width (mm) | 50 |

| Maximum workpiece length (mm) | 250 |

| Workpiece Module | 1.0 - 4.0 |

| Maximum workpiece rotation speed (min-1) | 10,000 |

| Wheel spindle rotation speed (min-1) | 3,000 |

| Wheel outer diameter (mm) | 400 |

| Floor area Width x depth x height (mm) | 4,380×3,810×2,683 |

| Machine weight (kg) | 11,000 |

You can download the product catalogue for this product.

Product catalogue downloadIf you would like a product catalog, please fill in the necessary information on the dedicated form.

You can download the catalogue in PDF format.

*Catalogs are not available for some products.

Product catalogue download