KANZAKI Map

The head office building, located on the same premises as the factory, houses functions such as development, design, and sales, and the first floor displays our precision, historic products.

We will provide information that will satisfy our customers from a comfortable and warm space.

In spring, the garden on the premises, where about 40 cherry trees bloom, is opened to the public and a Cherry Blossom Festival is held.

This is a local event that is attended by approximately 1,200 people, mainly local residents.

This is a testing facility specializing in the evaluation of electric products, with a view to responding to the need for a carbon-free society.

From the second floor corridor, you can observe the testing process through glass.

We are equipped with various facilities that enable us to check product performance from multiple angles, and we build safety and quality into the products we develop.

In addition, the data and ideas gained from testing are fed back into development at every stage, ensuring that we create durable, reliable products.

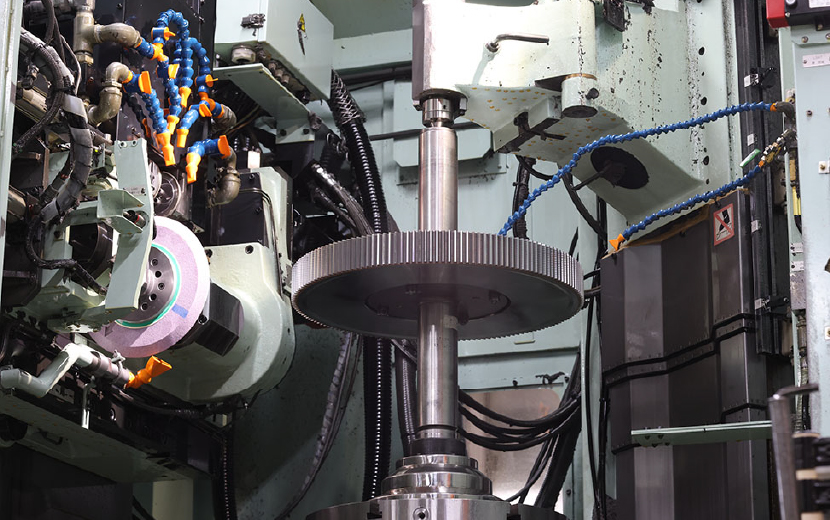

Our gear factory has a history of over 50 years and handles all processes of gear processing in-house, from machining to heat treatment and polishing. We manufacture approximately 4,000 types of products annually, including transmission gears and bevel gears for agricultural machinery, gears for small engines and gas turbines, and gears for marine engines and clutches.

We are also a manufacturer of various machine tools, including shaving machines, and we apply our accumulated technology to gear production to continue providing our customers with better products.

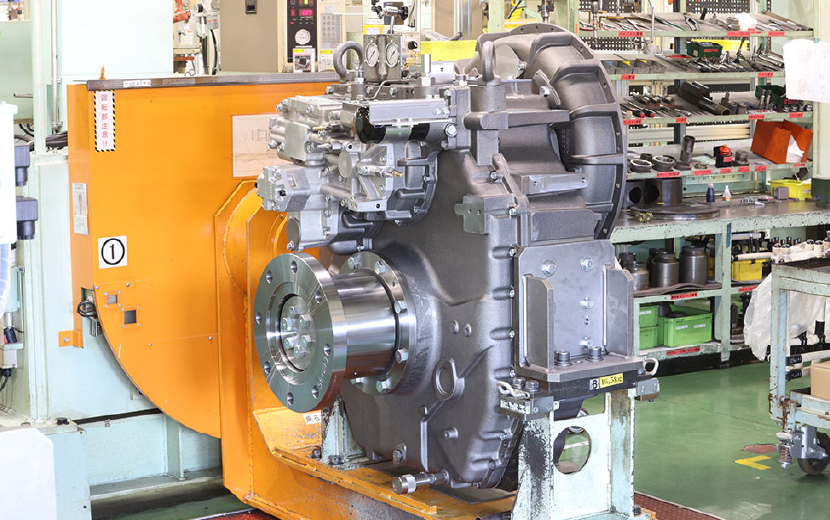

At our machine tool factory, we manufacture gear processing machines such as gear shaping machines, gear deburring machines, gear shaving machines, gear honing machines and gear grinding machines, as well as vertical lathes used for processing automobile part pistons and tire wheels, as well as thermal deburring machines and assembly equipment for overseas production bases.

As a gear manufacturer, we also feed back the technology we have accumulated into our machine tools, and continue to provide better products to our customers.

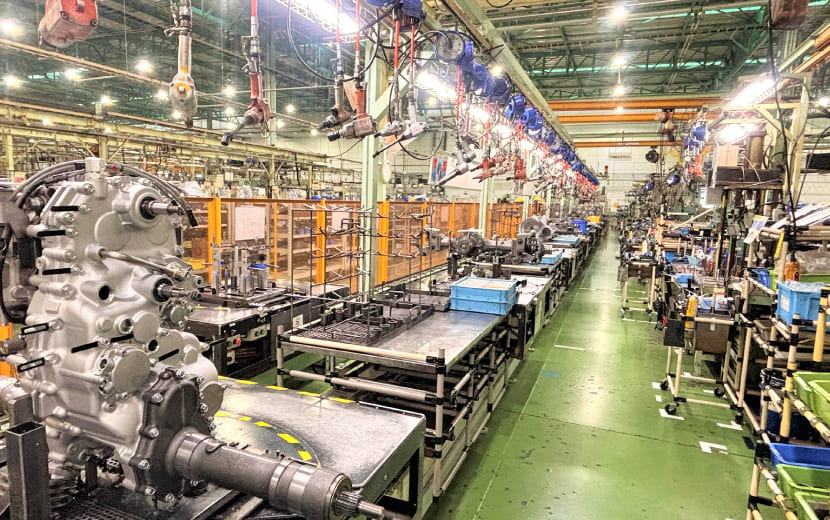

We manufacture transmissions for combine harvesters and lawn mowers, as well as marine gears for commercial and recreational use, and associated hydraulic equipment such as valves, pumps, and motors.

We assemble and paint each unit individually using parts processed in-house and parts purchased from partner manufacturers, and then provide them to each user.

The facility is equipped with a wooden terrace, a dining room, a training room, a large public bath, a powder room, etc.

Digital signage provides the latest information about the company and information about employee benefits.

The test course, which is approximately 2,500 m² in size, is equipped with slopes on both sides of grass and concrete, allowing us to test actual equipment in a variety of environments and conditions.

Kanzaki transmissions are developed through numerous rigorous testing on test courses.