Gear Processing Machine

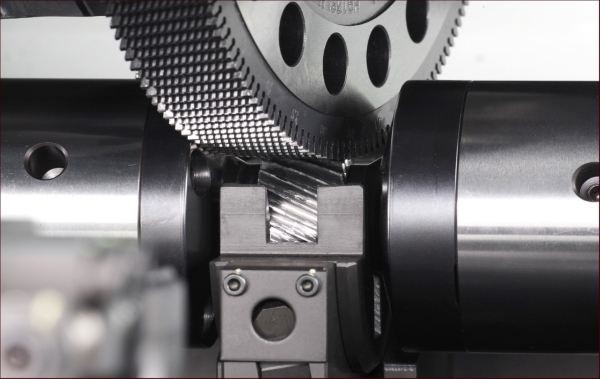

Gear Shaving Machine

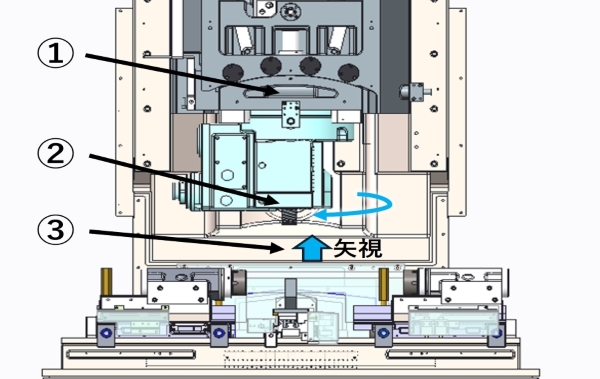

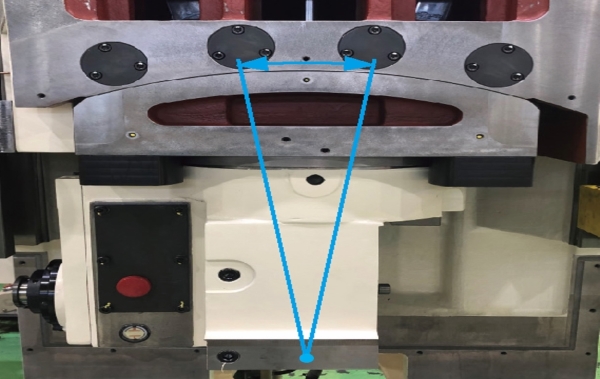

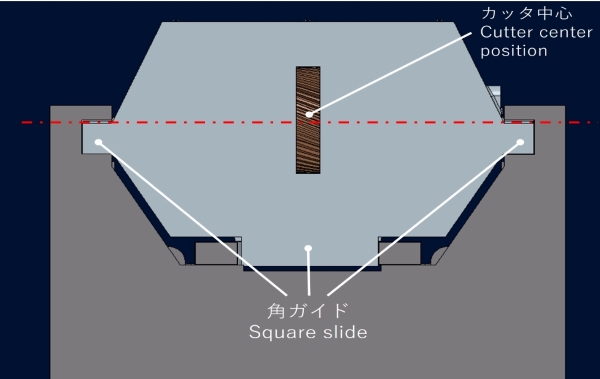

The latest model reflects user needs, with improved mechanical rigidity, a more compact structure, and improved operability.

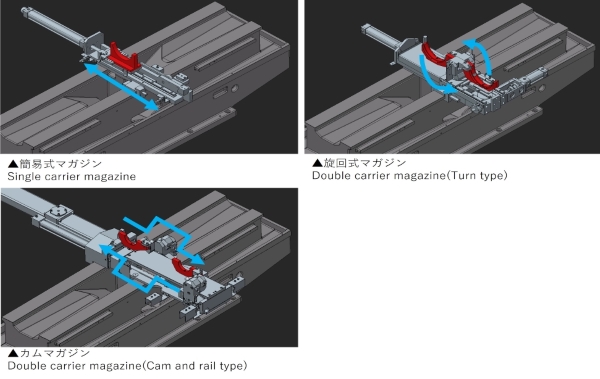

Improved setup and maintenance

| Part number | SX-350M-NC3 | SX-350L-NC5 |

|---|---|---|

| Maximum workpiece outer diameter (mm) | 350 | 350 |

| Maximum workpiece face width (mm) | 40150 | |

| Maximum workpiece length (mm) | (From the machine perspective) ±240 |

(From the machine perspective) ±350 |

| Maximum workpiece module | 5 | 5 |

| Distance between left and right centers (mm) | 480 | 700 |

| Table stroke (mm) | − | ±75 |

| Maximum spindle speed (min-1) | 400 | 400 |

| Floor area Width x depth x height (mm) | 1,400×2,220×2,670 | 1,700×2,220×2,670 |

| Machine weight (kg) | 5,000 | 5,500 |

You can download the product catalogue for this product.

Product catalogue downloadIf you would like a product catalog, please fill in the necessary information on the dedicated form.

You can download the catalogue in PDF format.

*Catalogs are not available for some products.

Product catalogue download