- Top

- Technology

- Base technology

- Analysis of our gears and their systems

Analysis of our gears and their systems

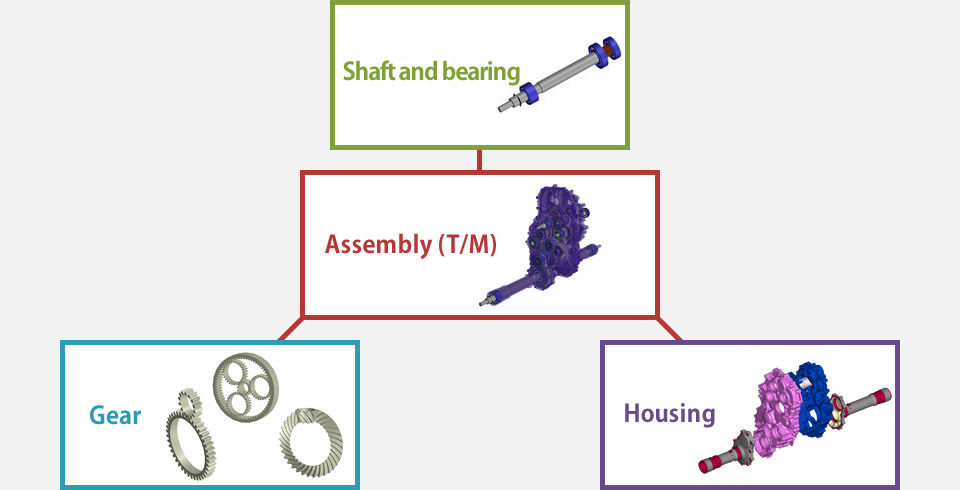

Each transmission is composed of gears, the shaft, the bearings, and the housing. To create precise and reliable products, we first produce a transmission using computer CAD drawings of each of these parts. Then, we run computer simulation tests and analyze the results according to project specifications before making the real product.

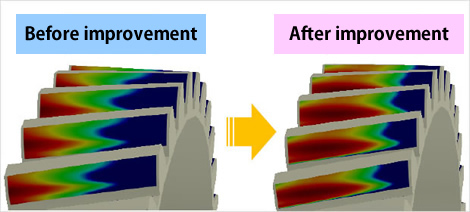

Analysis of transmission strength for agricultural use

The video to the left shows how housing distortion affects the gears and causes a decrease in strength.To fix this problem we adjust the shape of the gear, considering the distortion, in order to match it to the constraints.

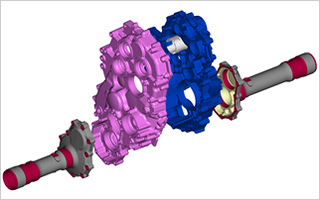

Analysis for the internal parts

Transmissions designed for the agricultural market have very complicated structures. In order to meet each customer's specific product needs, we go through a very in-depth process. We create a CAD model of the transmission, analyze the strength of the gears and housing, and then design it according to customer specifications.

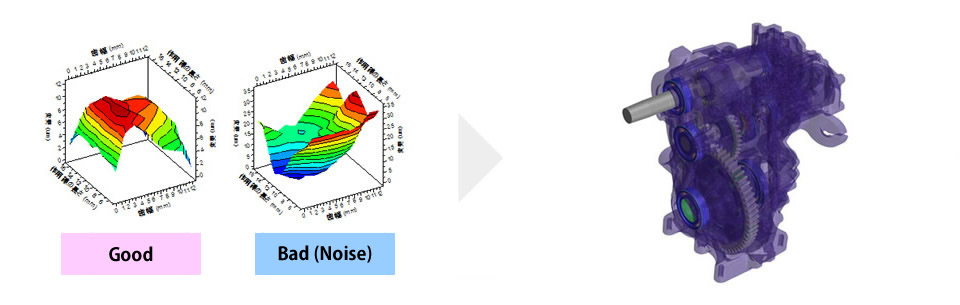

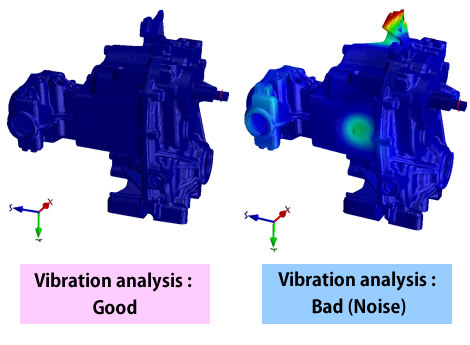

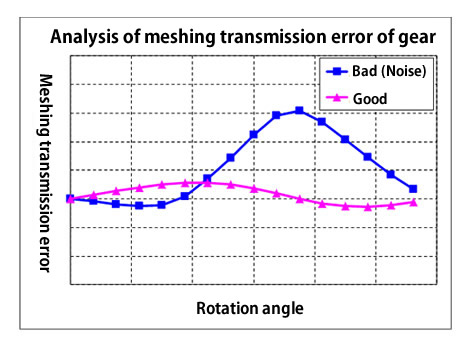

Noise analysis of an off-highway transmission

As UTV's become increasingly popular in the market, noise reduction solutions are being sought after. One cause of transmission noise comes from the gears. We can quantitatively analyze our gear designs and their vibration on the housing to develop a much quieter system.

- The other core technology