Viewing

Viewing

Vertical lathe

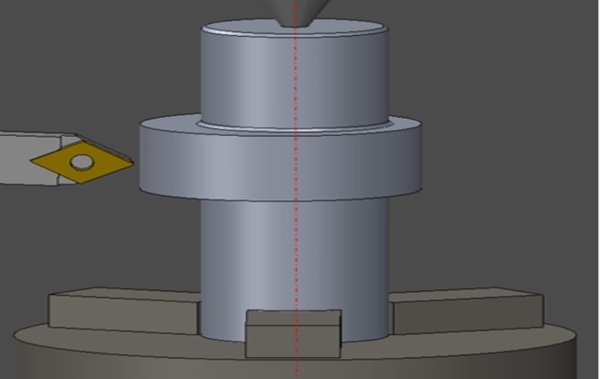

Non-circular processing machine

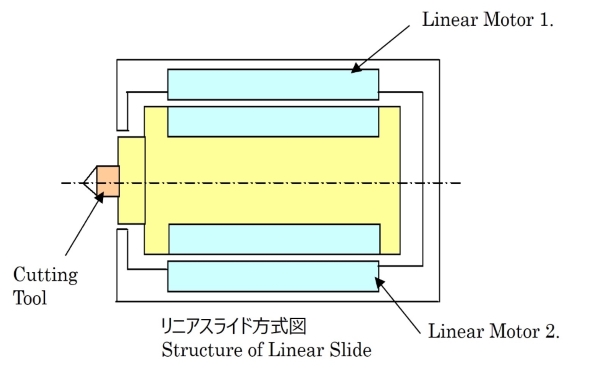

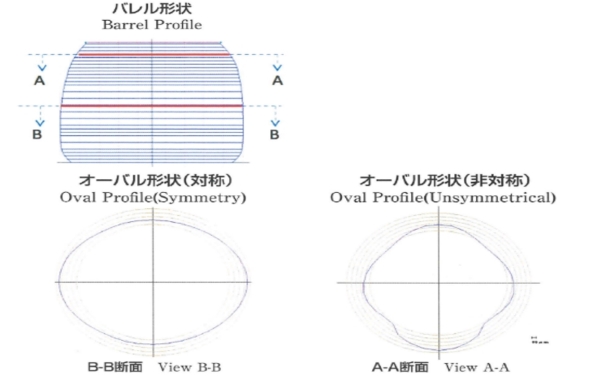

Synchronizing the Y-axis slide and main axis driven by a linear motor enables high-speed, high-precision machining of non-circular shapes.

Tail thrust is torque controlled, thrust changes are done via CRT input

Vertical space saving: Floor space of 2.0 m2 achieved

Linked lathe machining ←→ non-circular machining. Realizes cycle time reduction.

The software allows you to easily create machining programs by inputting data into a computer.

| Maximum swing (mm) | 220 |

|---|---|

| Appropriate machining diameter (mm) | ~φ120 |

| Appropriate processing length (mm) | ~100 |

| Spindle end shape | φ165 flat face |

| Maximum spindle speed (min-1) | 4,500 |

| X-axis maximum slide stroke (mm) | 180 |

| X-axis rapid traverse speed (m/min) | 12 |

| Z-axis maximum slide stroke (mm) | 195 |

| Z-axis rapid traverse speed (m/min) | 18 |

| Maximum Y-axis slide stroke (mm) | 2.5 |

| Tailstock stroke diameter (mm) | φ80 |

| Tailstock stroke movement (mm) | 110 |

| Floor area Width x depth x height (mm) | 1,190×1,620×2,250 |

| Machine weight (kg) | 3,000 |

You can download the product catalogue for this product.

Product catalogue downloadIf you would like a product catalog, please fill in the necessary information on the dedicated form.

You can download the catalogue in PDF format.

*Catalogs are not available for some products.

Product catalogue download